Electrical Power Tools: A Complete Guide for Professionals and DIY Enthusiasts

In today’s fast-paced and productivity-driven world, electrical power tools have become essential for both professional contractors and DIY homeowners. These tools offer greater efficiency, precision, and speed compared to traditional hand tools. Whether you’re building a deck, installing shelves, or working on an industrial-scale project, power tools save time and reduce physical strain.

This comprehensive guide explores what electrical power tools are, their types, uses, benefits, safety tips, maintenance advice, and the top brands dominating the market in 2025.

What Are Electrical Power Tools?

Electrical power tools are mechanical devices that operate using electrical energy—either through a direct connection to an outlet (corded) or powered by rechargeable batteries (cordless). They are designed to perform tasks that would otherwise require extensive manual effort or time, such as drilling, cutting, grinding, sanding, polishing, and fastening.

Power tools are categorized based on their energy source:

Common Types of Electrical Power Tools

1. Drills

Drills are among the most common and versatile tools. They are used to bore holes in wood, metal, plastic, and masonry.

-

Cordless drills for portability

-

Hammer drills for concrete and masonry

-

Right-angle drills for tight spaces

2. Saws

Electrical saws allow for quick and precise cutting.

-

Circular Saws – Ideal for straight cuts in wood or metal

-

Jigsaws – Used for intricate or curved cuts

-

Reciprocating Saws – Great for demolition work

-

Table Saws – Preferred in woodworking workshops

3. Grinders

Angle grinders and bench grinders are used for grinding, cutting, and polishing.

4. Sanders

Power sanders smooth surfaces quickly and evenly.

-

Orbital Sanders

-

Belt Sanders

-

Detail Sanders

5. Impact Drivers and Wrenches

These tools deliver high torque and are essential for driving large fasteners or bolts.

-

Impact Drivers – Compact and excellent for screws

-

Impact Wrenches – Heavier-duty, often used in auto repair

6. Rotary Tools

Miniature power tools ideal for engraving, grinding, and polishing.

7. Heat Guns

Used to apply hot air for stripping paint, shrinking tubing, and other applications.

Benefits of Using Electrical Power Tools

✔️ Time Efficiency

Electrical tools significantly cut down the time it takes to complete a task. For example, drilling with a cordless drill takes a fraction of the time compared to using a manual hand drill.

✔️ Precision and Consistency

Modern tools are engineered for high precision, ensuring consistent and accurate results with minimal errors.

✔️ Ease of Use

Power tools reduce the physical effort required, making tasks easier for professionals and DIYers alike.

✔️ Versatility

From woodworking to metal fabrication, power tools offer functionality across a wide range of applications.

✔️ Increased Productivity

Especially in industrial settings, power tools allow workers to perform more tasks in less time, boosting productivity.

Corded vs Cordless: Which Is Better?

Corded Tools

Cordless Tools

-

Pros: Portability, flexibility to work anywhere

-

Cons: Limited battery life, often less powerful

Best choice? For mobile or on-site tasks, cordless is often more convenient. For heavy-duty, continuous work, corded tools are usually the better option.

Safety Tips for Using Electrical Power Tools

Using power tools improperly can lead to serious injury. Here are essential safety precautions:

-

Read the Manual – Always understand how a tool operates before using it.

-

Wear PPE – Use safety glasses, gloves, hearing protection, and masks.

-

Inspect Tools Before Use – Check for damage or defects.

-

Disconnect When Not in Use – Prevents accidental activation.

-

Secure Workpieces – Use clamps or vises to hold material in place.

-

Use the Right Tool for the Job – Avoid misusing tools.

-

Avoid Water – Electrical tools should never be used near wet conditions.

Maintenance Tips to Extend Tool Life

To keep your electrical power tools functioning optimally:

-

Clean After Use – Dust and debris can damage motors and moving parts.

-

Store Properly – Keep tools in a dry, safe location.

-

Charge Batteries Properly – Don’t overcharge or fully deplete lithium-ion batteries.

-

Lubricate Moving Parts – Regularly oil parts that need friction-reduction.

-

Check Cords and Plugs – Damaged cords can pose safety risks.

-

Follow Service Intervals – Some tools need periodic professional servicing.

Top Brands of Electrical Power Tools in 2025

1. DeWalt

Known for its rugged build and long-lasting batteries, DeWalt is a favorite among professionals.

2. Makita

Renowned for lightweight designs and advanced brushless motors.

3. Bosch

Offers precision German engineering in their drills, saws, and measuring tools.

4. Milwaukee

Popular for its cordless M12 and M18 tool systems.

5. Ryobi

Best known for affordability and homeowner-friendly features.

6. Hilti

Industry-grade tools for heavy-duty construction projects.

Buying Guide: How to Choose the Right Power Tools

Here’s what to consider when purchasing power tools:

Purpose of Use

Are you doing light DIY work or professional construction? This affects the type and grade of tool required.

Power Source

Choose between corded (continuous use) or cordless (portability).

Tool Weight and Ergonomics

Comfortable, well-balanced tools reduce fatigue during long sessions.

Accessories and Compatibility

Check if the tool system supports interchangeable batteries and accessories.

Budget

While professional tools are more expensive, they last longer and deliver better performance.

Applications of Electrical Power Tools

Electrical power tools are used across numerous industries:

-

Construction – Drilling, cutting, grinding, framing

-

Carpentry – Sanding, sawing, nailing

-

Automotive Repair – Impact wrenches, grinders

-

Plumbing – Pipe cutting, heat guns

-

Metalworking – Grinders, drills, welding prep

-

Home Improvement – Hanging shelves, mounting TVs, remodeling

Future Trends in Power Tools

In 2025 and beyond, the electrical power tool market is experiencing significant innovation:

Eco-Friendly Designs

Manufacturers are focusing on tools with lower emissions and recyclable components.

Advanced Battery Technology

Fast-charging, long-life lithium-ion batteries with smart charge cycles are becoming standard.

Smart Power Tools

Bluetooth-enabled tools that can track usage, battery levels, and location through mobile apps.

🔧 Modular Tools

Interchangeable heads and bases for multi-functionality with fewer tools.

1996-2002 Toyota 4Runner 3.4L V6 Remanufactured Engine 5VZ-FE 5VZFE *0 MILES / 6-Months Warranty*

1 × $3,499.00

1996-2002 Toyota 4Runner 3.4L V6 Remanufactured Engine 5VZ-FE 5VZFE *0 MILES / 6-Months Warranty*

1 × $3,499.00  JDM 2009-2013 Subaru Legacy 2.5GT 2.5L Turbo Automatic AWD Transmission ej255 tg5d8claab

1 × $499.00

JDM 2009-2013 Subaru Legacy 2.5GT 2.5L Turbo Automatic AWD Transmission ej255 tg5d8claab

1 × $499.00  Humminbird SOLIX 15 CHIRP MEGA SI Plus G3

1 × $730.00

Humminbird SOLIX 15 CHIRP MEGA SI Plus G3

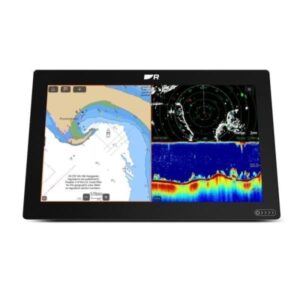

1 × $730.00  Raymarine Axiom 2 XL 19 Glass Bridge Chartplotter

1 × $2,100.00

Raymarine Axiom 2 XL 19 Glass Bridge Chartplotter

1 × $2,100.00  Raymarine Axiom 2 Pro 16 S Chartplotter/Fishfinder

1 × $1,700.00

Raymarine Axiom 2 Pro 16 S Chartplotter/Fishfinder

1 × $1,700.00  M12 Compact Wire Stripper

1 × $49.00

M12 Compact Wire Stripper

1 × $49.00  M18 Cable Cutter

1 × $199.00

M18 Cable Cutter

1 × $199.00