M18 FORCE LOGIC Press Tool: The Ultimate Solution for Efficient Plumbing and HVAC Connections

The M18 FORCE LOGIC Press Tool by Milwaukee is revolutionizing the plumbing and HVAC industries by offering a faster, safer, and more efficient method of making pipe connections. This powerful cordless pressing tool eliminates the need for traditional soldering, threading, or welding, enabling professionals to complete jobs with greater ease and precision. In this detailed guide, we’ll explore everything you need to know about the M18 FORCE LOGIC Press Tool — from its features, benefits, and applications to tips for choosing the right model and maximizing performance.

What is the M18 FORCE LOGIC Press Tool?

The M18 FORCE LOGIC Press Tool is a battery-powered pressing device designed to join pipes and fittings quickly and securely without heat or flame. It uses a hydraulic pressing mechanism to crimp fittings onto copper, stainless steel, and other compatible pipe materials, ensuring reliable, leak-proof connections.

Milwaukee Tool, a leading brand in power tools, developed the FORCE LOGIC system to provide professionals with a portable, easy-to-use alternative to traditional pipe joining methods. The M18 model operates on Milwaukee’s M18 REDLITHIUM battery platform, offering cordless convenience and long runtime.

Key Features of the M18 FORCE LOGIC Press Tool

Understanding the features of the M18 FORCE LOGIC Press Tool can help professionals decide why it’s the preferred choice for pressing applications. Here are the key highlights:

1. Cordless, Battery-Powered Operation

-

The tool runs on Milwaukee’s M18 REDLITHIUM batteries.

-

Offers cordless freedom, allowing operators to work in tight or remote spaces without needing power cords.

-

Compatible with all M18 batteries, providing flexibility for users already invested in Milwaukee’s ecosystem.

2. High-Force Hydraulic Pressing

-

The tool delivers up to 6 tons of pressing force.

-

It uses a hydraulic piston to form uniform crimps on a wide range of fittings.

-

This ensures durable and consistent connections every time.

3. Multi-Material Compatibility

-

Designed to work with copper, stainless steel, and carbon steel pipes.

-

Compatible with various press fittings from popular brands like Viega, NIBCO, and others.

-

Supports a wide range of pipe diameters, typically from 1/2 inch to 2 inches (12mm to 54mm), depending on the model.

4. Ergonomic and Compact Design

-

Lightweight and balanced to reduce operator fatigue.

-

Features an easy-to-use jaw design for quick loading and unloading of fittings.

-

Slim profile enables access in tight spaces often found in residential and commercial settings.

5. Fast Pressing Cycle

6. LED Indicators and Tool Feedback

-

Equipped with LEDs that indicate battery life, cycle completion, and tool status.

-

Some models offer audible feedback for confirmation.

7. Durability and Jobsite Ready

Benefits of Using the M18 FORCE LOGIC Press Tool

Switching to the M18 FORCE LOGIC Press Tool offers several benefits for plumbers, HVAC technicians, and mechanical contractors. Some of the main advantages include:

Increased Efficiency and Speed

-

Traditional pipe joining methods like soldering or threading can take significant time due to prep, heating, and cleanup.

-

The M18 press tool allows connections to be made in a fraction of that time, accelerating project completion.

Safer Working Conditions

-

Eliminates open flames or hot work, reducing fire hazards and the need for fire watches.

-

Ideal for work in confined spaces or near combustible materials.

-

Reduces risk of burns or heat-related accidents.

Versatility Across Applications

-

Works on multiple pipe materials, allowing one tool to handle various job types.

-

Compatible with many fitting systems, offering flexibility for different project requirements.

Quality and Reliability

-

Hydraulic pressing provides uniform pressure to ensure secure, leak-proof joints.

-

Reduces the risk of faulty connections caused by human error in soldering or threading.

Cost Savings Over Time

-

Less downtime and faster jobs mean reduced labor costs.

-

Lower risk of rework due to failed joints or leaks.

-

Minimal need for additional consumables like flux, solder, or pipe threading equipment.

Common Applications of the M18 FORCE LOGIC Press Tool

The versatility of the M18 FORCE LOGIC Press Tool makes it a preferred choice for many professional tasks, including:

Plumbing Installations and Repairs

-

Domestic and commercial water supply lines.

-

Hot and cold water pipe installations.

-

Retrofit jobs requiring fast pipe replacements without dismantling surrounding materials.

HVAC Systems

-

Installation of hydronic heating and cooling systems.

-

Chilled water pipe connections.

-

Air conditioning refrigerant piping.

Fire Protection Systems

Industrial and Commercial Piping

How to Choose the Right M18 FORCE LOGIC Press Tool Model

Milwaukee offers several versions of the M18 FORCE LOGIC Press Tool tailored to different needs and pipe sizes. When selecting the best tool, consider the following:

1. Pipe Size Range

-

Determine the diameter of pipes you commonly work with.

-

Smaller, more compact models are suitable for 1/2” to 1-1/4” pipes.

-

Larger tools can handle up to 2” or more.

2. Battery Compatibility and Runtime

3. Jaw and Fitting Compatibility

4. Weight and Ergonomics

-

For overhead or prolonged use, a lightweight and ergonomic tool reduces fatigue.

-

Check grip comfort and balance.

5. Budget and Kit Inclusions

-

Kits may include the tool, battery, charger, jaws, and carrying case.

-

Evaluate your budget but also consider the value of included accessories.

Maintenance Tips for M18 FORCE LOGIC Press Tools

Proper care ensures your press tool performs reliably and lasts longer:

-

Clean Jaws Regularly: Remove debris and residue after each use.

-

Check Hydraulic Fluid: Some models may require periodic hydraulic fluid checks.

-

Inspect for Damage: Regularly inspect jaws, housing, and battery contacts.

-

Store Properly: Keep the tool in a clean, dry place and use the provided case.

-

Charge Batteries Correctly: Use Milwaukee-approved chargers to maintain battery health.

Frequently Asked Questions (FAQs)

Q1: Can the M18 FORCE LOGIC Press Tool be used on plastic pipes?

A: No, the tool is designed for metal pipes like copper, stainless steel, and carbon steel. Plastic pipes require different joining methods.

Q2: How long does a battery charge last when using the press tool?

A: Runtime depends on battery capacity and usage intensity. Typically, an M18 REDLITHIUM High Output 5.0Ah battery can complete dozens of presses on a single charge.

Q3: Are the press fittings reusable?

A: No, press fittings are designed for single use. Once pressed, the fitting should not be removed or reused.

Q4: Is the M18 FORCE LOGIC Press Tool compatible with fittings from all manufacturers?

A: It is compatible with many popular fitting brands, but always verify jaw compatibility with the fitting manufacturer’s specifications.

Q5: How much does the M18 FORCE LOGIC Press Tool weigh?

A: Weight varies by model, but generally ranges from 6 to 9 pounds including battery, designed for easy handling.

Kobewel S200i Inverter Welding Machine 200A

1 × $462.88

Kobewel S200i Inverter Welding Machine 200A

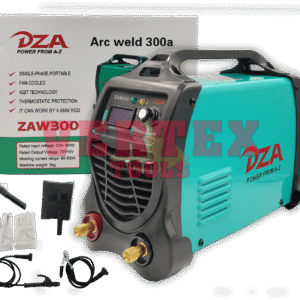

1 × $462.88  DZA ZAW-300 Digital DC Inverter ARC Welding Machine 300 Amps

1 × $48.82

DZA ZAW-300 Digital DC Inverter ARC Welding Machine 300 Amps

1 × $48.82  Daichi AC/DC Welding Machine

1 × $611.62

Daichi AC/DC Welding Machine

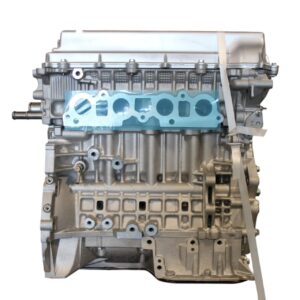

1 × $611.62  1995-1998 Toyota T100 3.4L V6 Remanufactured Engine 5VZ-FE 5VZFE *0 MILES / 6-Months Warranty*

1 × $3,499.00

1995-1998 Toyota T100 3.4L V6 Remanufactured Engine 5VZ-FE 5VZFE *0 MILES / 6-Months Warranty*

1 × $3,499.00  2000-2004 Toyota Tacoma 2.7L 4-Cylinder 4-Port Remanufactured Engine 3RZ-FE 3RZFE *0 MILES / 6-Months Warranty*

2 × $2,999.00

2000-2004 Toyota Tacoma 2.7L 4-Cylinder 4-Port Remanufactured Engine 3RZ-FE 3RZFE *0 MILES / 6-Months Warranty*

2 × $2,999.00  1984-1995 Toyota 4Runner 2.4L 4-Cylinder Brand New Engine 22R 22RE *0 MILES / 6-Months Warranty*

1 × $1,999.00

1984-1995 Toyota 4Runner 2.4L 4-Cylinder Brand New Engine 22R 22RE *0 MILES / 6-Months Warranty*

1 × $1,999.00  Garmin GPSMAP 8622 With Mapping

1 × $2,400.00

Garmin GPSMAP 8622 With Mapping

1 × $2,400.00  1995-2004 Toyota Tacoma 3.4L V6 Remanufactured Engine 5VZ-FE 5VZFE *0 MILES / 6-Months Warranty*

1 × $3,499.00

1995-2004 Toyota Tacoma 3.4L V6 Remanufactured Engine 5VZ-FE 5VZFE *0 MILES / 6-Months Warranty*

1 × $3,499.00  Hi-Tronic MIG 251GF DC Inverter Welding Machine 2in1 (MIG/ARC)

1 × $665.59

Hi-Tronic MIG 251GF DC Inverter Welding Machine 2in1 (MIG/ARC)

1 × $665.59  2003-2008 Toyota Matrix 1.8L Remanufactured Engine 1ZZ-FE 1ZZFE *0 MILES / 6-Months Warranty*

1 × $1,999.00

2003-2008 Toyota Matrix 1.8L Remanufactured Engine 1ZZ-FE 1ZZFE *0 MILES / 6-Months Warranty*

1 × $1,999.00  Ingco ING-MMA32062 Inverter MMA Welding Machine 320A Industrial 320A

1 × $198.76

Ingco ING-MMA32062 Inverter MMA Welding Machine 320A Industrial 320A

1 × $198.76  M18 Transfer Pump

1 × $199.00

M18 Transfer Pump

1 × $199.00

There are no reviews yet.